The pervasive use of technology has brought about a tremendous growth in data as well as an explosion in scaling and complexity of integrated circuits. That trend continues as the focus on reducing cost and increasing performance enables a growing number of applications.

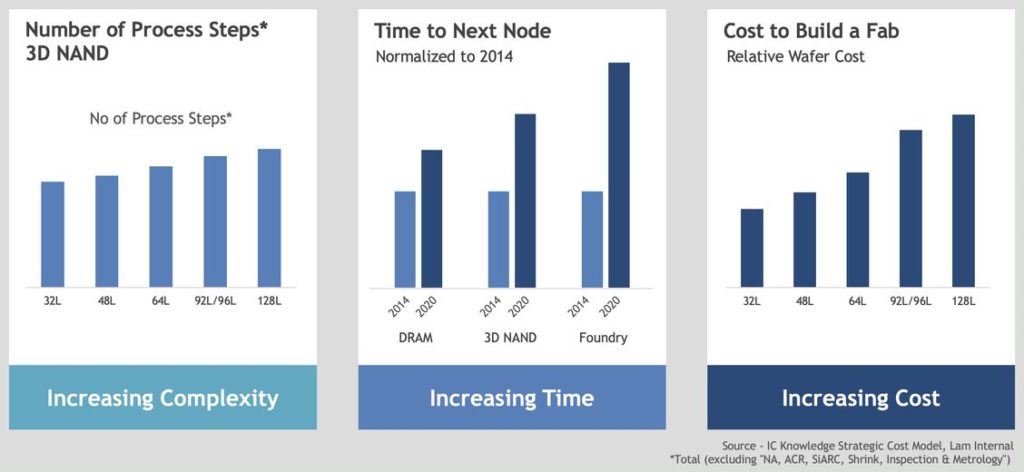

The complexity of manufacturing processes and equipment needed to address this trend has thrown up its own set of challenges as every new generation of devices requires additional innovation and additional process steps (figure 1). The time to transition from one node to the next is increasing as is the cost of R&D and manufacturing capacity build-out.

Figure 1: The increase in the number of layers and process steps has added complexity that is affecting time to next node and the relative wafer cost.

Lam Equipment Intelligence®

Lam’s efforts are aimed at addressing these challenges by enabling customers to achieve faster technology transitions at lower costs and with fewer resources, while generating less waste. This means not only speeding up R&D toward higher device performance, but reaching high-volume manufacturing (HVM) at a lower cost.

Lam Equipment Intelligence® deals with this using its four foundational pillars of digital twin/digital thread, virtual process development, smart tools, and digital services, which incorporate data-driven modeling, virtualization, and artificial intelligence (AI) at every point in the process of designing, developing, sourcing, building, and supporting systems and processes as they move from concept through feasibility to HVM.

Digital Twin and Digital Thread

Over 40 years and hundreds of products deployed in fabs, Lam has managed product development with various applications, and created and maintained data related to those products. These systems have evolved from paper, to files, to databases. Every data point is a marker along the life of a system as it journeys from its initial concept to end of life.

At the same time, as manufacturing execution systems (MES) in a fab move wafers in process (WIP) and maintain equipment, data lakes are created from process tools and metrology. Additionally, Lam customers generate more data in their own R&D and design spaces.

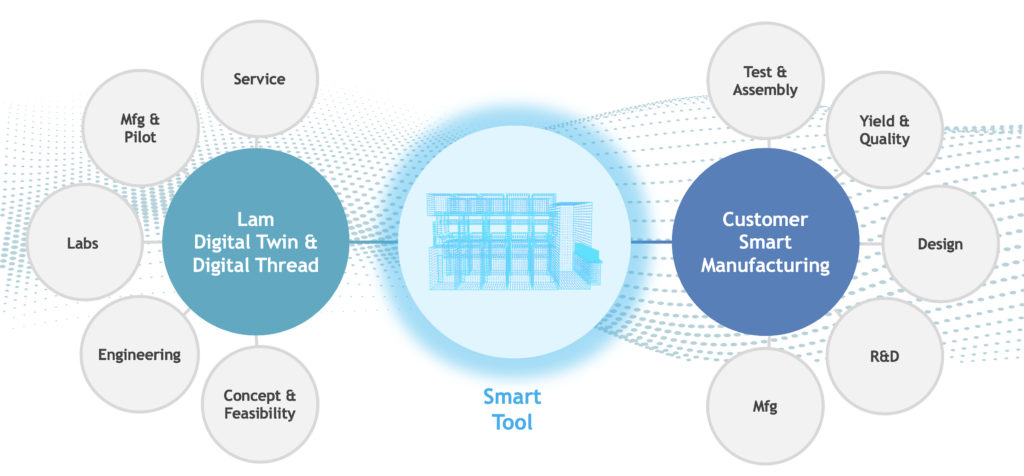

All of this data is critical to the vision of Equipment Intelligence® – the digital twin and digital thread are woven across all capabilities needed to realize this future (figure 2).

Figure 2: The amount of available data is exploding with improving systems. For instance, a fleet of Lam etchers today can generate nearly 1TB per day, up from about 5GB per day a decade ago.

Lam’s strategy is to start with a digital twin and expand the digital thread content throughout the lifecycle of the tool from concept and feasibility in Lam engineering to supporting operations in a customer factory. However, connecting ever-growing data from different sources so that it is collected, collated, and tagged with the relevant context presents an enormous challenge.

Today’s SEMI Equipment Communications Standard / Generic Equipment Model (SECS/GEM) that uses the High-Speed SECS Message Services (HSMS) interface typically gets between five and ten percent of the generated content off Lam’s advanced process tools. The company has therefore developed standard interfaces to move more data from the tools into customer systems and back such that it allows running edge applications on Lam platforms. This coupling of digital information improves system availability and performance.

Virtual Process Development

Scaling to Moore’s Law has required increasing the number of control parameters and improving capability. Lam, for instance, has added RF generators to etch tools, increased RF frequencies, introduced new etch gas chemistries, and allowed these inputs to be pulsed in both the time phase as well as amplitude.

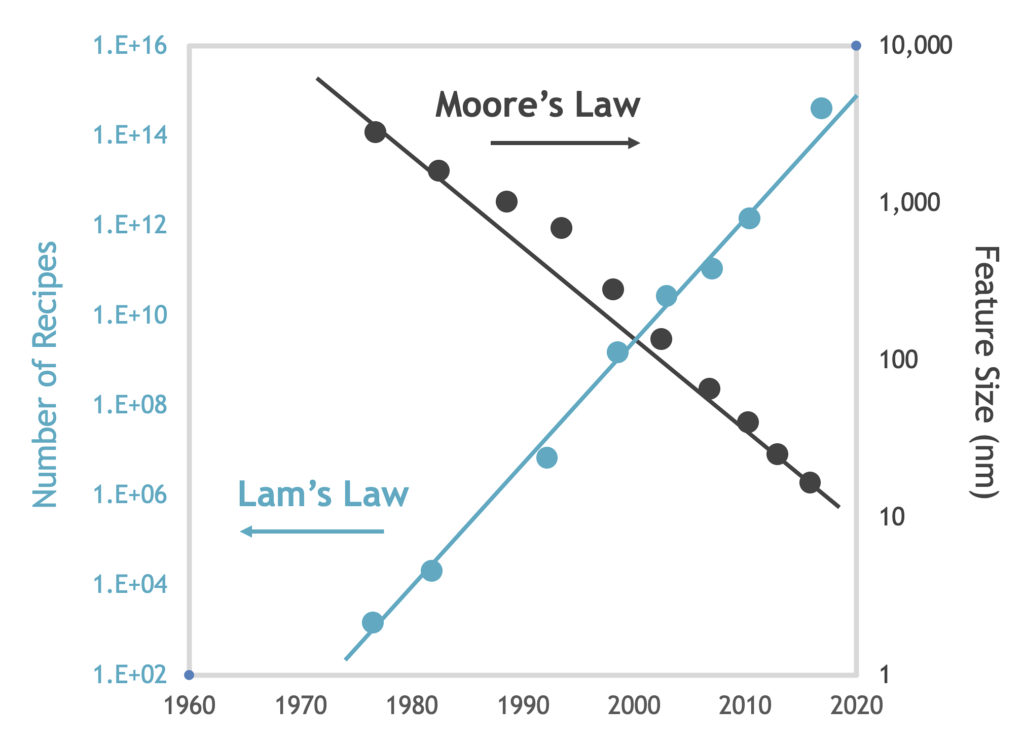

Higher capability has come with complexity, creating a demanding development environment. Finding the one solution out of 1014 possible process combinations for etching a 5nm device, for instance, may take months of running a large number of experiments. This growth in the number of potential solutions to process challenges is described by what we refer to as Lam’s Law (figure 3). Over the last decade, the cost of developing and qualifying recipes has increased by a factor of 10. If left unchecked, it will jeopardize the industry’s productivity goals and future advances.

Figure 3: Lam’s Law presents growth in the number of potential solutions to process challenges as fabs scale devices to Moore’s Law.

Purely physics-based models of etch and deposition are too multi-faceted and computationally intensive to yield practical results. Virtual process development, on the other hand, uses computable models that combine physics with machine learning and historical data mining to quickly eliminate bad paths and dial in the right combination of equipment variables. This extension of the digital twin into the process space has, even in its initial phase of implementation, reduced the design of experiment (DoE) count and cost by over 20 percent.

Smart Tools

The digital twin and the virtual process development dovetail with smart tools. For, once the optimal process has been discovered, semiconductor manufacturers must replicate it with acceptable tolerances within angstroms on hundreds of chambers, running hundreds of thousands of wafers per month. Matching chamber performance requires smart tools and intelligent services.

Lam’s approach to creating smart tools is to make them self-aware, adaptive, and self-maintaining. Self-aware tools know which parts, software, and configurations are installed and can monitor key performance metrics using sensors. With adaptive capabilities, smart tools can perform consistently and adjust to compensate for unit process drift and incoming material variation, or to optimize productivity. Self-maintenance extends productive output by scheduling and automatically performing tasks like calibrations and cleans.

For instance, Lam’s latest generation etch product, Sense.i™, is powered by Equipment Intelligence® with more sensors than previous-generation tools (figure 4). It autonomously self-calibrates, has self-maintenance capabilities and uses machine learning to adapt to process variations.

Figure 4: Lam’s approach to smart tools is to make them self-aware, adaptive, and self-maintaining. The Sense.i™ etch platform (left) and the ALTUS® LFW (right) integrate Equipment Intelligence®.

The tool sensor data can be captured and analyzed to identify patterns and trends and specify actions for improvement. When combined with customer fab information, this can reduce chamber matching times from weeks to days. Sense.i’s intelligent system architecture for adaptive learning optimizes performance not only within a single tool, but across a fleet of tools.

In the deposition space, tools like VECTOR® Strata® for 3D NAND stack deposition, Striker® for ALD and ALTUS® LFW for tungsten metallization will also incorporate Equipment Intelligence®. The products already have millisecond sensing and data monitoring capabilities. Maintenance continues to be automated through software, and Lam is expanding their fleet level analytics and chamber matching capabilities.

Equipment Intelligence®, however, needs an on-site repository of equipment data that allows customer access and control while maintaining integrity. This repository is essential for diagnostics, trending, AI-based application development, edge computing, and even on-tool computing.

Lam has addressed this need with a data repository, which pipes data in a high-density format out of the company’s tools. Standard interfaces take the data into customer Big Data systems and make it available for Lam experts to conduct diagnoses and create maintenance algorithms for customers in their fabs.

Digital Services

Profitability is dependent not on a single chamber or even a fleet of chambers, but in maximizing the good die coming out of those chambers over time. Smart tools offer new opportunities to achieve this by allowing digitization of service and enabling a revolutionary new digital workforce.

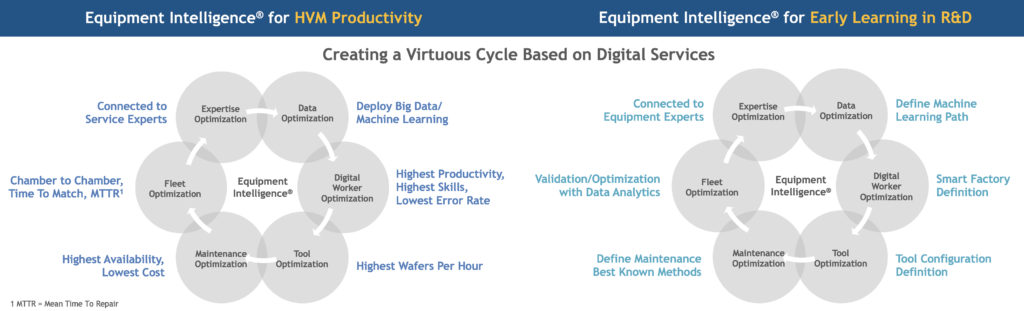

The “virtuous cycle” of digital services starts with tool data optimization to ensure the right data is curated and made available at the right place (figure 5). Next comes knowledge management from installation to maintenance or troubleshooting, including real-time point of use access, for customers and field service engineers. Lam achieves this digital worker optimization through mobility tablets.

Figure 5: The virtuous cycle of implementing digital services helps increased productivity in the HVM environment and early learning in R&D.

The next step is ensuring tool optimization through simulation and eventually AI, and automatically maximizing throughput. Digital services help increase repeatability and reduce human variability in routine maintenance, and achievement first-time-right goals in troubleshooting and service tasks. Tool fleet management and optimization is achieved by leveraging the tool-data-rich environment and AI-enhanced multi-variate analyses for fleet matching and predictive maintenance. Finally, scaling expertise through remote technologies enables faster problem solving and steeper HVM ramps.

While these benefits are primarily accrued in ramp-up to volume, they start in R&D where digital services help to define and test the capabilities needed for HVM. Consistent applications of Equipment Intelligence® technology across customer development, ramp to yield, and HVM provide for faster learning and better profitability.

Augmented and Virtual Reality

Augmented and virtual reality (AR/VR) are key technologies in remotely delivering digital services. They enable remote training as well as expert support and live-feed-based advice during operations, increasing safety and reducing the burden of travel on people and the planet.

Lam has started using AR/VR to train the workforce on new tools, and it has enabled the company to continue to support customers during the ongoing pandemic. Since last year, Lam has seen the use of advanced analytics double, digitally enhanced services triple, and remote support increase by six times. This has highlighted Equipment Intelligence® service technologies as critical tools for business resilience.

Transition to Lam Equipment Intelligence®

It is increasingly clear that collaboration is key to achieving the full benefit of Lam Equipment Intelligence® and the current crisis has become a force behind breaking barriers and accelerating progress.

The industry must continue the transition from today’s loosely stitched boxes to nodes on a network where data flows back and forth, and algorithms from various parties contribute to achieving greater control at a lower cost of ownership. Jointly embracing the full potential of Equipment Intelligence® will enable the next milestones on the industry’s technology roadmap.