-

Addresses key manufacturing challenges and significantly improves wafer yield

-

Builds on Lam's 15-year heritage of innovation in bevel solutions

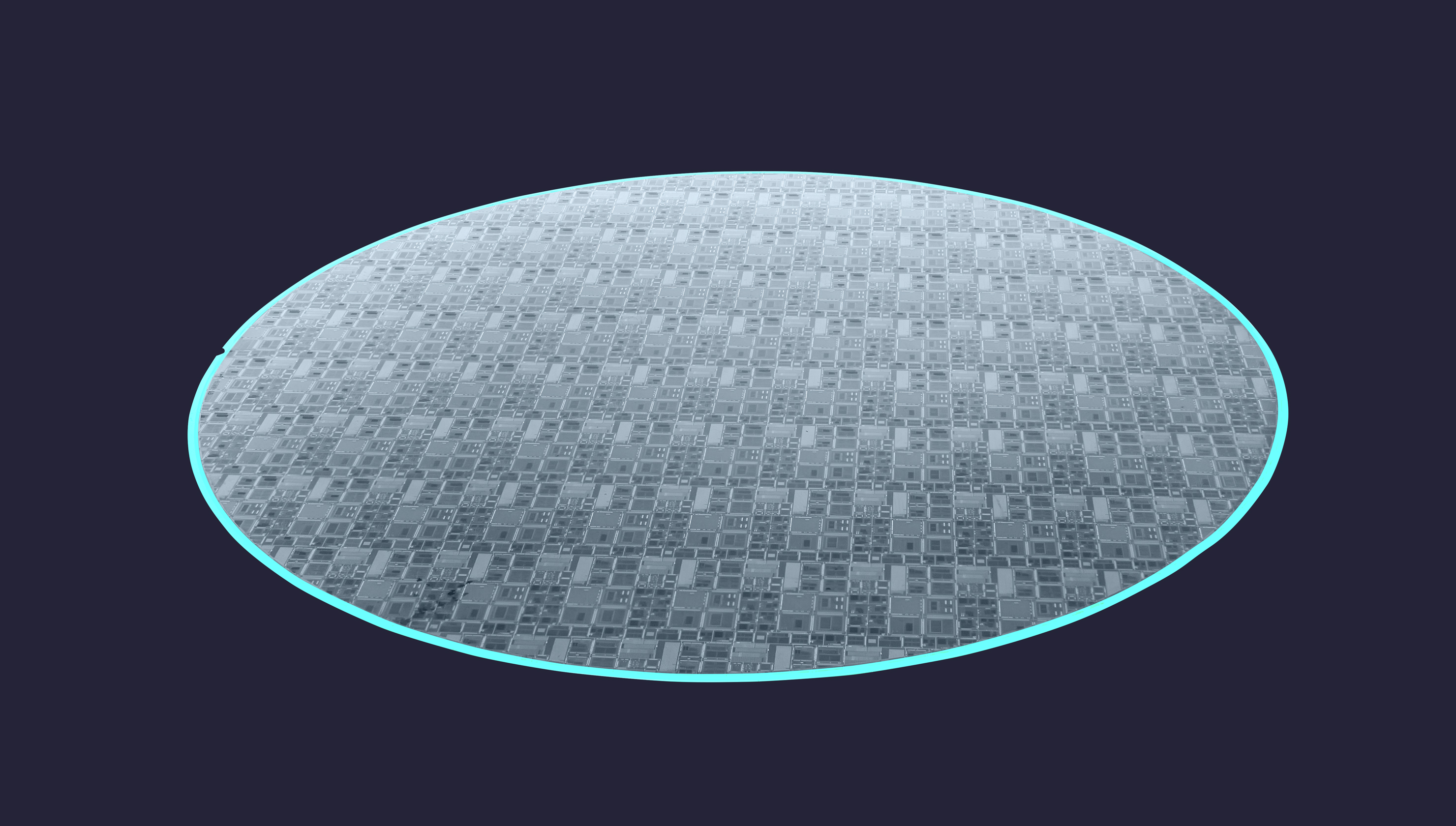

For more than 15 years, Lam’s Coronus® product family has been the leader in wafer bevel technology. Today we introduced the newest member of the family, Coronus DX. It’s the industry’s first bevel deposition solution optimized to tackle key manufacturing challenges in next-gen logic, 3D NAND and advanced packaging applications.

As semiconductors continue to scale, manufacturing has become more complex and costly. Hundreds of process steps are needed to build nanometer-sized devices on a silicon wafer. In a single step, Coronus DX deposits a proprietary layer of protective film on both sides of the wafer edge, which helps prevent damage that can often occur during advanced production. This powerful protection helps drive more predictable manufacturing and significantly higher yield, paving the way for adoption of advanced logic, packaging and 3D NAND production processes that weren't commercially feasible until now.

First introduced in 2007, the Coronus product line is used by every major semiconductor manufacturer, with several thousand chambers installed globally. Coronus products incrementally increase wafer yield for chipmakers, delivering an additional 0.2 to 0.5 percent of yield per etch or deposition step. Our customers are realizing the value of Coronus. Here’s what they have to say:

-

KIOXIA Group, 3D NAND maker: “Improving quality in the production process through advancements in areas such as bevel technology is essential to our ability to provide next-generation flash memory at scale to our customers. We look forward to continuing to work with Lam Research and its Coronus solutions to enable leading-edge wafer production.”

-

Leading foundry logic provider: “Advanced packaging features the higher density and improved performance of smaller form factors that helps us remain competitive. Lam’s innovative Coronus DX solution provides robustness and reliability in manufacturing that enables us to meet our customers’ unique packaging requirements.”

Read this press release or visit the Coronus product family webpage to learn more.

Allison Parker manages technology PR for Lam.

Caution Regarding Forward-Looking Statements

This article contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include any statements that are not statements of historical fact, including statements regarding the impact of Coronus DX on key manufacturing challenges and on wafer yield; the protective effect of films deposited by Coronus DX; benefits afforded by Coronus DX, including predictability of manufacturing; the impact of Coronus DX on the adoption of advanced logic, packaging and 3D NAND production processes; and the impact of Coronus DX on robustness and reliability in manufacturing. Forward-looking statements are subject to risks and uncertainties that could cause actual results to differ materially from the expectations expressed, including the risks and uncertainties described in our filings with the U.S. Securities and Exchange Commission, including specifically the Risk Factors described in our annual report on Form 10-K and quarterly reports on Form 10-Q. You should not place undue reliance on forward-looking statements. We undertake no obligation to update any forward-looking statements.