- Video games and virtual and augmented reality are driving demand for haptics

- Lam’s pulsed laser deposition capability can enable next-gen haptics technology

Imagine an immersive virtual experience where your sense of touch seems every bit as real as the sights and sounds of the digital world you’re exploring. Feel the sensation of catching a ball in your hands or the keys clicking on a virtual keyboard, even though they only exist in cyberspace. The sensations are the results of haptic technologies enabled in part by innovations from Lam.

Why it matters: Manufacturing micro-scale haptic devices requires many of the same basic processes used to make integrated circuits—deposition, etching, cleaning, and more—but without the need to fabricate nano-scale structures. Lam’s Reliant® Systems group, which adapts and extends technologies so customers can manufacture innovative products, enables applications like haptics.

Electric Stimulation

Tactile sensations—such as pressure, texture, temperature, and vibration—contribute to our perception of reality. Haptic technologies simulate these impressions by converting electronic signals to mechanical signals.

Haptic devices are already part of our everyday lives. Most smartphones confirm a key press with a tactile “click” or vibration. Smartwatches and touchpads all use haptics to signal various actions. Touchscreens use haptics to imitate the feeling of pressing a button or flipping a switch.

- Growing interest in virtual and augmented reality is driving the development of new haptic technologies and applications.

- Driving and flying games build haptics into their steering wheels or controllers to simulate rough roads or choppy weather.

Tactile Pixels

Among the most-promising haptic technologies are piezoelectric materials, which create an internal electric field in response to applied pressure. Conversely, they expand or contract in response to an applied electrical field.

- A thin piezoelectric film, suspended over a cavity and fixed at its edges, flexes up and down in response to an electrical signal. This Piezoelectric actuator can be made exceedingly tiny, with some designs reaching sizes as small as a few millimeters or even smaller.

- Imagine a glove covered with an array of taxels (tactile pixels; tiny piezoelectric tactile elements) that can be controlled in a way analogous to the pixels in a visual display. With appropriate manipulation, they can simulate a limitless range of tactile sensations.

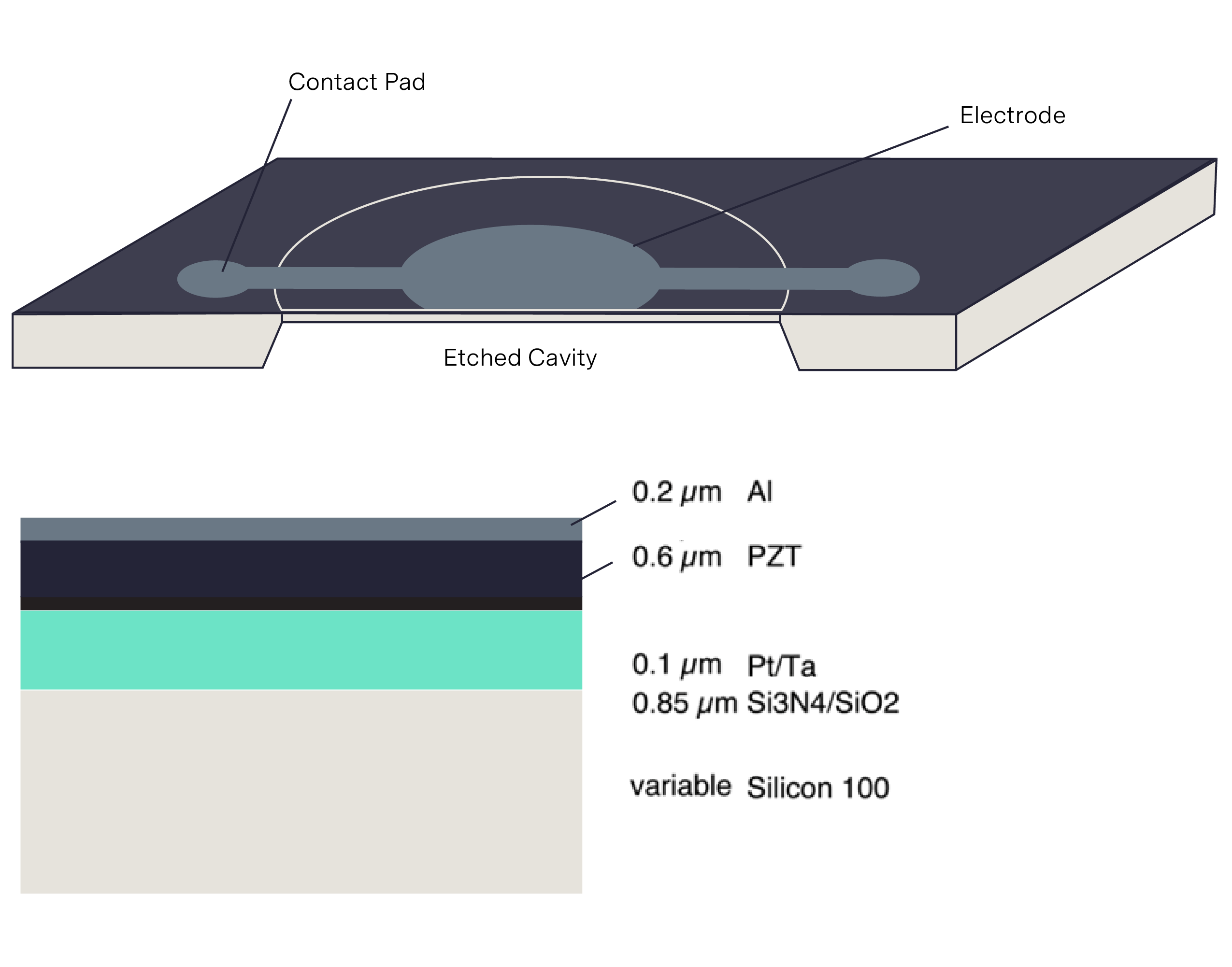

This figure illustrates a fabrication process for a piezoelectric actuator, depositing textured thin PZT (lead zirconium titanate) films on metal electrodes using silicon nitride and/or oxide as the membrane material.

A schematic drawing of the membrane with view onto the top side of the wafer and a schematic cross section through the films. (Graphic derived from "Piezoelectric actuation of PZT thin-film diaphragms at static and resonant conditions," Sensors and Actuators a-Physical, 1996.)

PZT Alternative

A promising alternative to PZT is scandium-doped aluminum nitride (ScAlN), which removes the use of lead. Because ScAIN has a superior breakdown voltage, similar mechanical displacement values can be achieved at thinner piezo thickness as compared to PZT.

- Breakdown voltage refers to the maximum voltage that can be applied to the actuator before it experiences a breakdown or failure in its electrical insulation.

- In general, the strength of the piezoelectric effect grows stronger with increasing scandium levels, but only up to a certain maximum level.

Lam Research’s pulsed laser deposition (PLD) products are well suited for ScAlN.

With pulsed laser deposition a short laser pulse vaporizes material from a small target positioned above the substrate, creating a deposition plume. The material is then deposited on the substrate below.

- The plume is about the size and shape of an apple, so achieving a uniform deposition over a large substrate requires multiple shots at multiple locations.

Some of the important advantages of PLD are its ability to deposit a wide variety of materials, including ScAlN, and the ability to fine tune the characteristics (such as within wafer film thickness and stress) of the deposited film.

Lam’s innovations in PLD of ScAlN may prove to be a key facilitator for the high-volume production of lead-free piezoelectric haptic devices and enable a sensational future.

For more information, email us!

Michelle Bourke is a managing director of Strategic Marketing for the Customer Support Business Group (CSBG); top photo credit

You might also like Radio Frequency Filters for 5G: Their Manufacturing Challenges and Why They’re Worth the Trouble

Caution Regarding Forward-Looking Statements This letter contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include any statements that are not statements of historical fact, including statements regarding the role of Lam’s innovations in PLD of ScAlN in facilitating the production of lead-free piezoelectric haptic devices. Forward-looking statements are subject to risks and uncertainties that could cause actual results to differ materially from the expectations expressed, including the risks and uncertainties described in our filings with the U.S. Securities and Exchange Commission, including specifically the Risk Factors described in our annual report on Form 10-K and quarterly reports on Form 10-Q. You should not place undue reliance on forward-looking statements. We undertake no obligation to update any forward-looking statements.