- Pulsed laser deposition enables specialty technologies, like RF filters and MEMS microphones

- PLD’s advantages over conventional deposition can enable next-gen applications

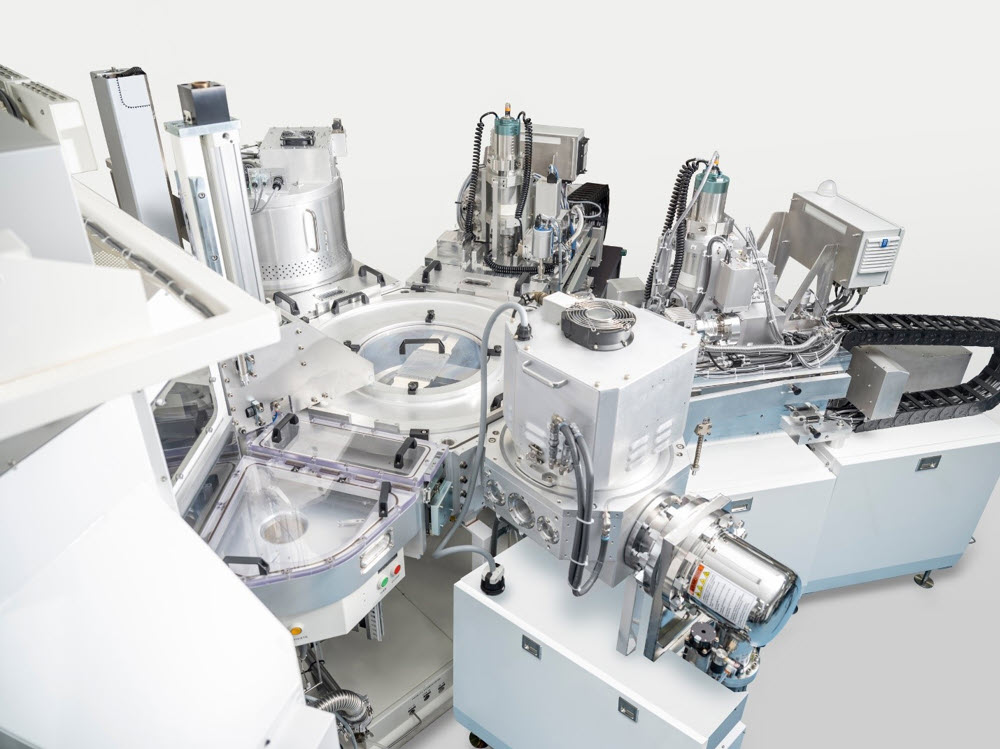

Pulsus™ – bringing pulsed laser deposition to wafer-level mass production

Lam Research hopes to revolutionize microchip manufacturing with the launch of a new system: Pulsus™.

Why it matters: For the first time in semiconductor production, Lam is using lasers to deposit thin films and bringing pulsed laser deposition (PLD) to wafer-level mass production. Pulsus is expected to be key in developing cutting-edge specialty technologies devices, such as RF (radio frequency) filters for 5G and Wi-Fi 6 and high-end MEMS (micro-electromechanical systems) microphones.

Specialty Technologies

Specialty technologies play a critical role in connecting the physical and digital worlds and help enable the modernization of the global economy. They allow us to connect the analog world in which we live to the digital world, such as advanced computing and AI.

Included in specialty technologies are MEMS (micro electro-mechanical systems) image sensors, power management solutions, local edge compute capability, conversion for analog signals, and RF connectivity solutions.

- RF filters: Radio frequency filters are electronic devices that tune in selectively on a specific data transfer frequency band. This allows your phone or device to send and receive high rates of data without interference, so improving the quality of communication.

- MEMS (micro-electromechanical systems): This is the technology of micro-scale devices incorporating both electronic and moving parts. For example, MEMS technology is incorporated in audio devices, micromirrors and micro-speakers.

Specialty technologies enable key functionalities in a vast array of day-to-day applications in automotive, mobile communications, healthcare, retail, manufacturing, and industrial automation.

The combination of these applications helps realize the increasingly smart world we live in. At Lam Research, our continued innovation is aimed at ensuring we have the products at 200 mm and 300 mm to meet these needs.

Adding Pulsus

In 2022, Lam acquired Solmates, a pioneer in the development of wafer-level PLD systems. Two years on, Solmates’ PLD expertise and Lam’s deep experience in deposition have combined to bring a new PLD system to high volume manufacturing, addressing the technical challenges of the materials needed for next generation RF filters and MEMS based devices.

The addition of Pulsus PLD to the Lam portfolio further expands our comprehensive range of deposition, etch and single wafer clean products focused on specialty technologies and demonstrates Lam’s continuous innovation in this sector.

Game Changer

PLD stands out for its ability to deposit high-quality multi-element thin films, crucial in the precision-driven world of microchip manufacturing. This technique offers unique capabilities, making it a game-changer for the industry.

- Take, for example, the manufacture of RF filters and MEMS microphones. For these devices, the level of scandium (Sc) is the critical factor enabling performance. Conventional deposition techniques such as reactive sputtering show a saturation in performance at scandium levels of around 30%. Lam’s PLD technology enables higher quality films of 40% Sc and above with higher performance than films deposited by conventional techniques.

The benefits of PLD compared to conventional deposition techniques include:

- Versatility to deposit complex materials, especially ceramics such as scandium aluminum nitride (AlScN)

- Higher quality films – providing higher device performance

- Advanced film control – Within-in-Wafer (WiW) uniformity tuning of thickness and stress

Uniform Films

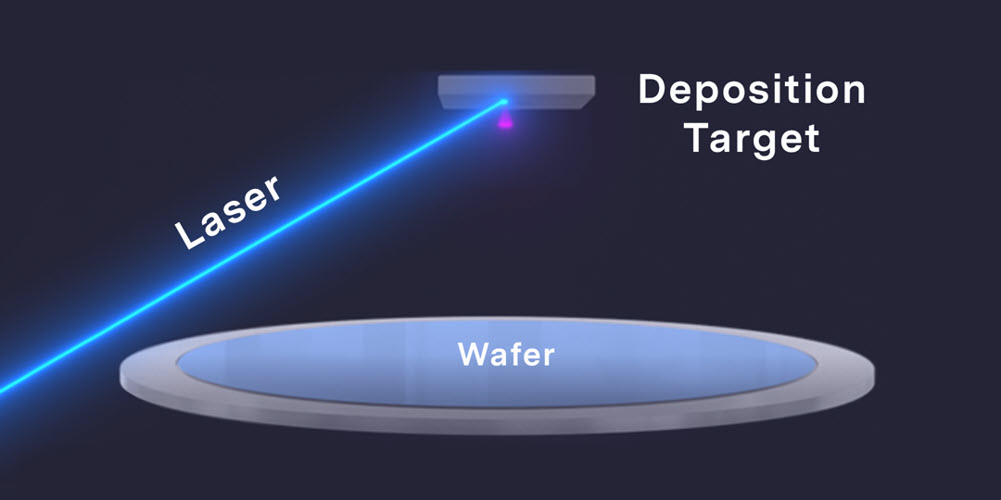

How does PLD work? A high-power laser beam strikes a target material in a vacuum chamber, creating a plasma plume that deposits thin layers onto a wafer. This process is essential for enabling high-quality, uniform films with precise control over thickness and stress.

PLD works differently from other deposition techniques, such as sputtering or atomic layer deposition (ALD):

- If we think of deposition in terms of rain, then sputtering is like a moderate, general rainfall that slowly forms pools on the ground.

- ALD could be compared to morning dew saturating the grass,

- PLD, in contrast, is a localized, heavy shower hovering over the landscape.

PLD’s Benefits

Depositing high performance thin films with PLD helps expand and accelerate our customers’ roadmaps. Lam's PLD equipment is designed to deliver cost-effective, high-volume manufacturing solutions while ensuring exceptional uniformity and quality. This efficiency is crucial in boosting manufacturing yields and staying competitive.

A lead-free alternative: Pushing the scandium concentration in AlScN enhances the piezo electric force. This, combined with the integration advantages of this material, makes it a prime candidate for a lead-free alternative to the piezoelectric material, lead zirconate titanate (PZT).

Looking ahead: PLD has the potential to drive the next generation of Specialty Technologies, including RF filters for 5G and WiFi6, high-end MEMS microphones, and other MEMS applications. Pulsus brings new and exciting materials to the semiconductor industry. Stay tuned...we’re just getting started.

Arjen Janssens is senior director, PLD

Caution Regarding Forward-Looking Statements

This article contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include any statements that are not statements of historical fact, including statements regarding market and industry expectations and the performance of the Pulsus system. Forward-looking statements are subject to risks and uncertainties that could cause actual results to differ materially from the expectations expressed, including the risks and uncertainties described in our filings with the U.S. Securities and Exchange Commission, including specifically the Risk Factors described in our annual report on Form 10-K and quarterly reports on Form 10-Q. You should not place undue reliance on forward-looking statements. We undertake no obligation to update any forward-looking statements.